Years of

Experience

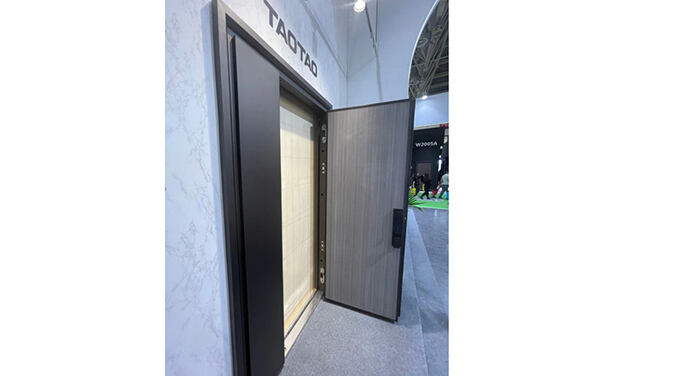

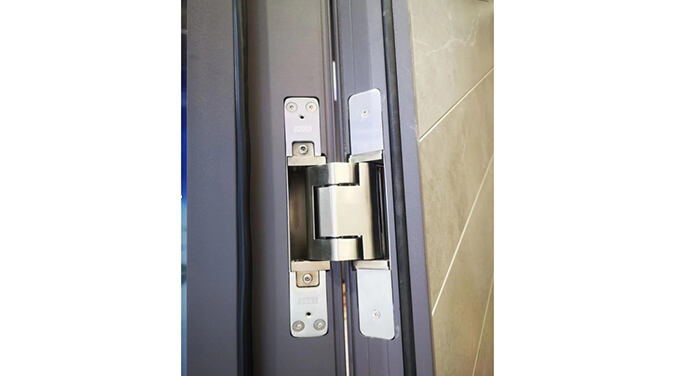

Jibang is a global manufacturer of precision parts and components. Our main service areas are 3D hidden hinge,door locksand other major industries. We are positioned to become a reliable partner in the mid-to-high end market,and it is our pursuit and commitment to provide reliable services for high quality companies in various sub-sectors.Jibang currently have 1000 workers which including 50 engineers,60 quality workers and 800 production workers. The land area covering 20,000㎡ and 28000㎡ structure area.

Island area

Years of R&D

experience

Production workers

Structure area

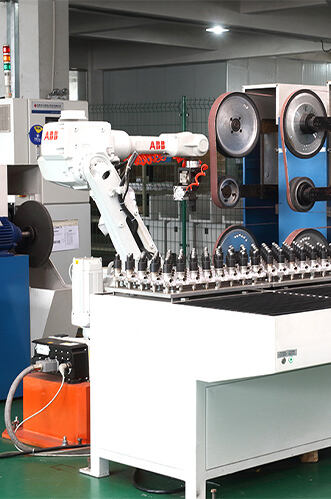

Our company has sophisticated equipment to assist production.

For steel production,shot blasting machine is an inevitable equipment,and the use of shot blasting machine for steel sand and steel ball surface treatment,is also an essential process,is to remove steel sand,steel ball surface stains,rust and check the product surface integrity of a necessary procedure,is essential.

The inspection machinery and electrical control part of the equipment and the image processing system are integrated

Air tightness testing machine is mainly used to detect the leakage of various sealing products,such as food packaging,medical equipment,household appliances and so on. These products need to maintain a certain tightness during use to prevent gas leakage or the intrusion of external pollutants. Through the air tightness test,the problem of poor product sealing can be effectively found and solved,so as to improve the quality and safety of the product.

The constant temperature and humidity machine can provide a stable working environment to ensure the quality and efficiency of the production process. It can prevent the impact of humidity changes on product quality and ensure the accuracy of experimental results.

The working principle of ultrasonic dry cleaning is that through the air circulation system,cleaning parts transmission system,ultrasonic system will be high-speed air flow and ultrasonic joint action to make the dirt particles out of suspension,ultrasonic reflection will be driven by the particles,by the vacuum adsorption chamber of the cleaning head suction and separation,and finally complete the cleaning.

The automatic shell line of the manipulator is mainly to solve the application problem of the contact and interaction between the mechanical arm and the outside world.

We provide our customers with integrated metal forming solutions and use “one-stop” services to help customers integrate supply chain resources and achieve “managed” manufacturing. The manufacturing process covers mold making,lost wax casting,stamping and bending,precision machining,surface treatment,and assembly testing. The product range includes the design and manufacture of precision casting parts,stamped and drawn parts,and precision machined parts.

The market is very challenging and our company will ensure your prices are both reasonable and competitive. This way,you can attract more customers and gain an edge over the competition.

We have obtained patents for our main products,which are of high quality and innovation. We offer OEM and ODM services to global brands,meeting their diverse and customized needs.

We have a professional QA team that follows strict test procedures to ensure the quality of our products to improve our performance.

We have a responsive sales team that listens to our customers and provides them with the best solutions. We also ensure on-time delivery,so that our customers can receive their products as soon as possible.